What are low-carbon façades and structures?

The façade and structure are key parts of any rehabilitation project, not only in terms of carbon weight, but also, first and foremost, because the idea is to complete a project. As mentioned earlier, the environmental work amounts to reflecting on the impact of every single material used.

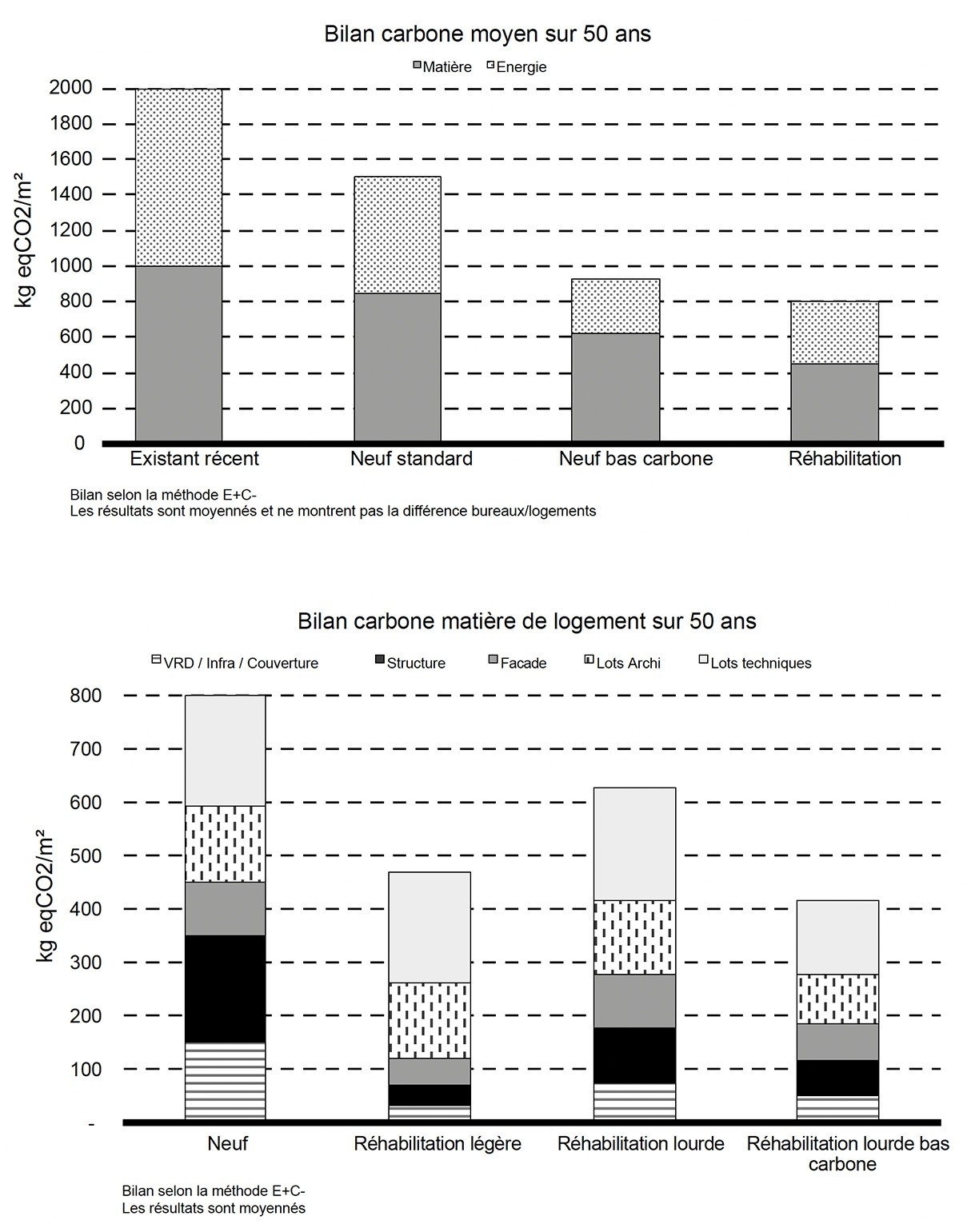

The first rule is that the façade must now first be optimized for its CO2 emissions, in priority over energy-related criteria. This is a dramatic change in approach for architects and engineers, who were previously subject to thermal regulations[12], the only objective of which was to lower our energy use. The new regulatory standards, RE2020, which came out in 2021[13], goes almost entirely in the direction of carbon and imposes a maximum carbon threshold above which construction isn’t possible. This regulation doesn’t apply to rehabilitation, but its logic and the fact that a heavy rehabilitation often calls for an entirely new façade allows us to draw analogies.

We now know that certain façade types[14] improve a building’s carbon impact. This approach should therefore dictate that of appearance and form. We also know that glazed sections are the primary weak spot of our impacts, both due to energy losses and to embodied carbon[15]. A fully glazed façade (with double or triple glazing) that contributes major energy gains can have a final weight of more than 300 kg CO2eq/m², whereas a low-carbon façade can go below under 100 kg CO2eq/m². From the perspective of material-related carbon weight, this second type of façade is the only one that can allow under 800 kg CO2eq/m² on the entirety of the building.

For a watchful eye, it’s easy to appreciate a building’s carbon weight simply by considering its façade, especially given that the form of a building, its complexity, and its compactness, are all strictly correlated to its impact. Certain architects follow the principle of “form follows function”; we now must adhere to the precept of “form follows carbon.” Quite efficient in that regard, Haussmannian buildings are part of the way forward.

It is no exaggeration to state that, in the case of a Haussmannian building, a carbon-oriented rehabilitation can lead to conserving 200 kg CO2eq/m² on materials and 150 kg CO2eq/m² on energy use, thus achieving, without too much trouble, a weight of 85 kg CO2eq/m², or, to put it another way, only about half as much as that of a new build.

Among the optimizations in our example is also the fact that no additional space is being created. Instead, the existing surface is densified with the use of bio-based materials, and sobriety in the improvements. This leads to two concerns. On the one hand, users must be supported in order to make them understand the issues around a project that has smaller or shared spaces, and how they can reduce their own carbon weight. On the other hand, programming itself must be geared towards low carbon. Building parking for cars rather than bicycles, for example, is a programmatic decision that can heavily constrain a project.

As we’ve seen, although the new façades of Tour Montparnasse are very carbon intensive, they allow for a major gain in terms of energy-related carbon weight. The particularity of this building also lies in its technical and mechanical constraints, as well as the natural ventilation system, which necessarily adds a lot to its overall carbon weight.

Let us now evoke structure. Structural remodeling should always be carried out using bio-based materials, which are much lighter and versatile. Though these materials may require complex engineering, their use is nevertheless increasingly widespread. But their primary benefit is that emissions are shifted in time as they only appear at the end of their service life. When this time lag comes in addition to a very long service life of the building, we can then talk about carbon storage. Though the use of wood may seem an obvious choice, we can also use other types of structure, such as raw earth or stone, and only resort to concrete, ideally a “low-carbon”[16] form, only if no other material can be used in its place.

Just as for the façade, we must review our ways of thinking. For example, concrete, and all the processes that we have been using thoughtlessly these past three years, since the last regulatory update, mustn’t be the first solution proposed, even though it appears straightaway. We are pleased to note that the RE2020 standards emphasize bio-based materials thanks to the adoption of a new calculation method referred to as the DLCA or Dynamic LCA (life cycle assessment)[17]. Based on this kind of calculation, an unoptimized structure can now achieve a lower weight of about 150 kg CO2eq/m², while a very low-carbon, optimized structure can edge on 0 kg CO2eq/m².

That being said, there should be no self-congratulating when only the major items have been worked on. This approach must also be applied to all other budgetary items. The interior spaces and architectural lots of a rehabilitation must contribute to the carbon reduction effort. This is where reuse comes into play. As it has now become a real driver for many startups and nonprofits, designers, shops, and even insurers and sales platforms[18], there is no reason not to mainstream proposals in that field. In an office building for instance, using recovered false flooring or sanitary fixtures is very efficient. There is also a source of materials to be thought up regarding cable trays and ducts. In residential units, the reuse of sanitary fixtures and radiators is perfectly conceivable. Beyond these examples, everything remains to be reinvented from direct onsite reuse, that is, when elements are retained and reused in the rehabilitation project, to the use of materials recovered from other projects, and products that are used to manufacture a new material. We can mention the Centre Pompidou’s iconic glass “caterpillar,” which are being given a new lease of life in an office setting, or the Métisse insulating material, manufactured from recycled cotton recovered from scrap clothing as examples of this approach.

From a carbon standpoint, we can, without being too far off-base, consider that the carbon weight of reused materials is negligible. Reuse also has the benefit of alleviating the pressure we exert on resources and waste generation—which is just as fundamental.

Beyond reuse, frugality must guide each of our actions in the building sector. For instance, should we still be equipping office spaces both with false flooring and suspended ceilings in 2022?